Svetla printing: biodegradable plastic will reduce the cost of manufacturing parts for space

- Статьи

- Science and technology

- Svetla printing: biodegradable plastic will reduce the cost of manufacturing parts for space

Russia has developed an economical 3D printing technology for parts for aviation and space. It allows you to do without the use of expensive high-temperature equipment. The process is based on a composite thread made of metal powder and biodegradable plastic. The latter is removed by annealing after printing the workpiece. Then the metals are sintered at 700 degrees instead of 1300, as in classical metallurgy, forming monolithic refractory and heat-resistant alloys. How the technology will simplify production and reduce the cost of aviation and space parts is described in the Izvestia article.

How to print heat-resistant products at low temperature

Scientists at the A.A. Baykov Institute of Metallurgy and Materials Science of the Russian Academy of Sciences have proposed a new method for 3D printing parts for aviation and space. The innovation will make it possible to produce durable, lightweight and heat-resistant products without expensive high-temperature processing, which will reduce the cost of production. The Ministry of Education and Science of the Russian Federation told Izvestia about this.

As the researchers explained, the basis of the development was a composite filament consisting of two thirds of a metal powder — a mixture of aluminum, titanium and nickel — and a third of a polymer polylactide. This biodegradable plastic, obtained from plant raw materials, first holds the shape of the future product, and then is completely removed.

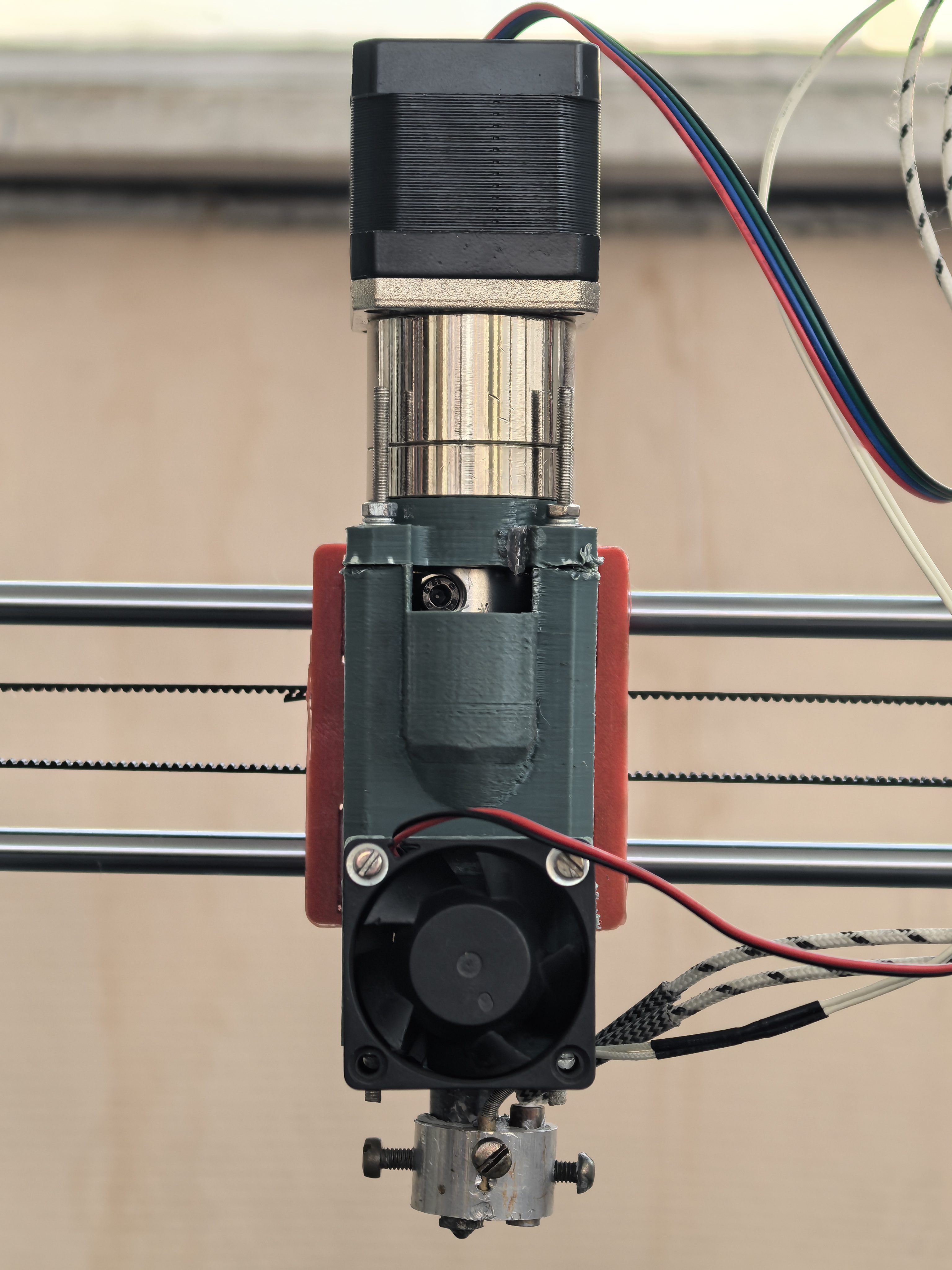

— The printing process is carried out on specially designed equipment. It ensures stable operation with metal polymer composites. After the blank is created, it is annealed in a vacuum furnace to remove the polymer matrix. This is followed by the main stage — sintering at a temperature slightly above +700 degrees," said Sergey Eremin, a researcher at the Laboratory of Additive and Digital Technologies of Polymer Composite Materials at the Institute of Physics and Technology of the Russian Academy of Sciences.

When heated this way, aluminum melts and starts a self-sustaining reaction with other metals. As a result, a new monolithic material with its own crystal lattice is formed. It has a high density and melts in its final state only at temperatures above 1300 degrees Celsius, the expert explained.

Thus, the proposed method makes it possible to circumvent the limitations of traditional metallurgy. It allows you to use relatively low temperatures to start a process that will eventually produce a material with a record high melting point. Also, the technology does not require expensive ingredients that are used in classical processing, the specialist noted.

According to him, the team is currently working to improve sintering modes, minimize the porosity of finished products and bring their strength characteristics to the level of materials obtained by classical powder metallurgy methods.

Where high temperature resistant alloys are used

— Heat-resistant materials are used, in particular, in the design of engines. For example, in the nozzles of rockets and aircraft turbines. They are also in demand in the elements of the skin, which protects the devices from overheating when they enter the dense layers of the atmosphere. In addition, such materials are used in hypersonic missile designs," Andrey Novikov, senior lecturer at the Department of Rocket and Space Composite Structures at Bauman Moscow State Technical University, told Izvestia.

Therefore, in his opinion, the development will accelerate the development of domestic satellite groups and the creation of new aircraft. At the same time, additive technologies are currently widely used not only in piece production, but also in large-scale production. For example, some metal parts in the latest iPhones are printed using 3D technology in large batches, he added.

— Reducing the processing parameters of materials from 1300 degrees to 700 degrees provides significant advantages. First of all, we are talking about energy. Eliminating the need for high temperatures means saving energy and simplifying the process compared to traditional high—temperature methods," explained Kamila Kydralieva, Professor at the Department of Advanced Materials and Technologies for Aerospace Applications at Moscow Aviation University.

However, the introduction of technology requires solving materials science, technological and regulatory problems, she noted. For example, the features of biocomposites should be taken into account. In particular, they can deform, and finished parts can be brittle. In addition, it is necessary to work out the processes of powder loading, printing, binder removal and sintering. It is important to ensure stable quality and uniform properties of the composite filament. Technology certification and confirmation of compliance with established standards will also be required.

— Temperatures of 1300 degrees and above require a different class of furnaces. They require complex lining, special heating elements, and more powerful thermal protection. The transition to a lower temperature range means that manufacturers can use widespread vacuum furnaces. This lowers the threshold for entry into the technology of small enterprises and scientific laboratories," said Sergey Nikiforov, an engineer at the Department of Laser and Additive Technologies at Kazan National Research Technical University named after A.N. Tupolev—KAI.

In his opinion, the researchers proposed a symbiosis of cheap polymer filament printing with metal filler and reactive sintering chemistry. The innovation is that aluminum is used not just as an alloying element, but as an activator. The weak points of the method include residual porosity and insufficient strength of finished products. In addition, when removing the polymer and subsequent sintering of metals, the product "dries up" and it is difficult to predict its exact final dimensions.

— The technology is considered to be well-established when the set parameters are consistently maintained from product to product. This is especially important for parts that are "put on the wing," commented the head of the Department of Engine Manufacturing Technologies at Samara National Research University. Academician S.P. Korolev, Alexander Khaimovich.

In order to bring laboratory development to production, it is necessary to create a stable technological process that allows to obtain the required quality in a limited range of parameters. They are conditioned by strict technical requirements for aviation and space materials, the specialist added.

Переведено сервисом «Яндекс Переводчик»