Wisdom tooth: an innovative biodegradable membrane can help rebuild the jaw

- Статьи

- Science and technology

- Wisdom tooth: an innovative biodegradable membrane can help rebuild the jaw

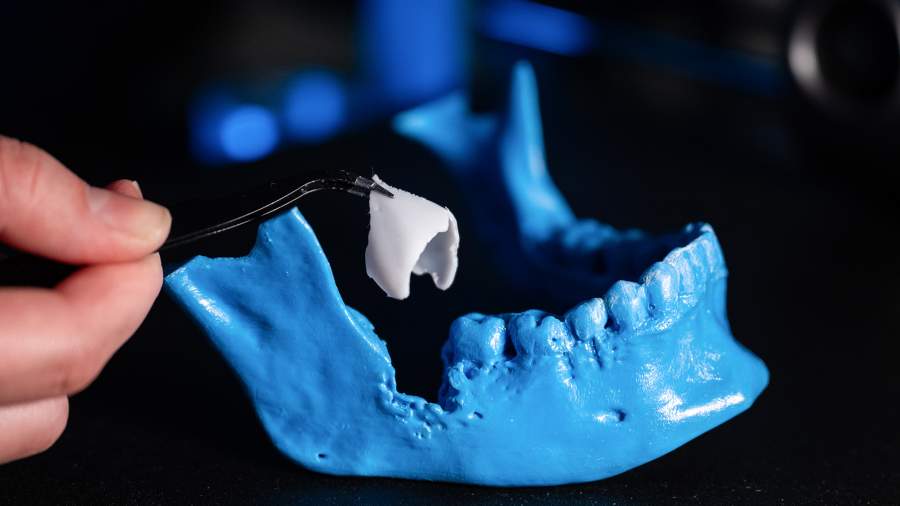

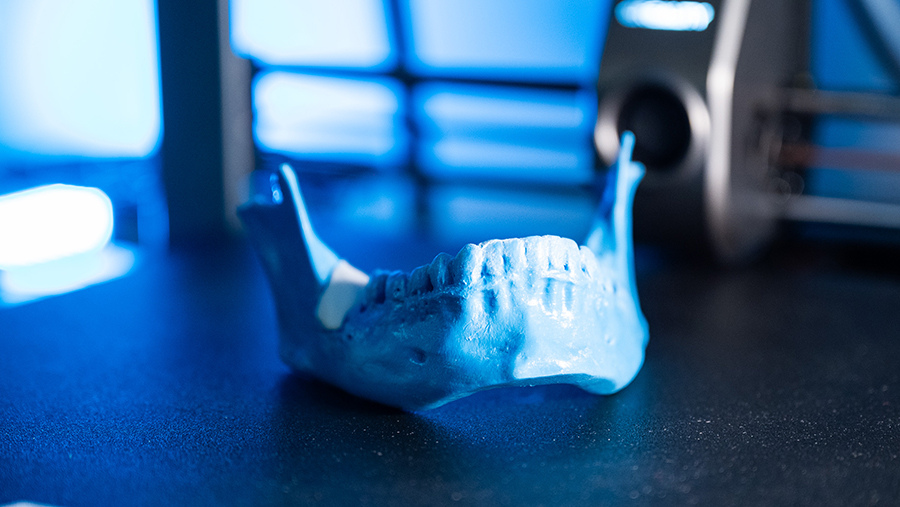

Russian scientists have created a personalized dental membrane, which is necessary for repairing damage to the jaw. The development is printed on a 3D printer to suit the individual characteristics of the patient. It acts as a barrier, protecting the bone cavity from overgrowth with connective tissue, allowing new bone to form. However, all existing membranes are either too soft or require repeated surgery to remove them. In contrast, the new development has optimal healing properties and degrades three to nine months after installation. According to dentists, the invention will noticeably simplify their work. However, for its introduction into practice, it must first be confirmed that, dissolving in the body, the material will not cause harm.

Dental membrane

NITU MISIS researchers have developed personalized dental membranes with antibacterial coating, which are designed to restore bone tissue of the jaw. Bone damage is a very common problem among dental patients. In order for it to properly repair itself, the resulting cavity needs to be protected by a barrier. It prevents overgrowth with connective tissue, and as a result, new bone is formed. However, all methods used today for this purpose have serious disadvantages. Most membranes are too soft, so they cannot be used to build up large amounts of bone. And if the medic uses a hard material, such as titanium, he has to perform a second operation to remove it. The new development of scientists can avoid these difficulties.

- Unlike analogues, personalized membranes reduce the risks of soft tissue damage and eliminate the need for additional processing. We used a composite material similar in properties to natural bone. Its high mechanical characteristics allow effective preservation of the space under the membrane for bone tissue restoration. The required biodegradation time is about three to nine months. Therefore, it was important to find a polymer that meets these requirements, - said the author of the project, a student of NITU MISIS Daria Stepanova.

The developers took into account all the advantages and disadvantages of currently available solutions and developed a durable bioresorbable membrane that can withstand mechanical loads for a long period of time for bone regeneration in the jaw area. The product is created on a 3D printer to fit the specific lesion. Once the polymer framework is implanted in the desired location, the structure safely dissolves after a few months. Therefore, repeated surgical intervention for extraction is not required. The polymer chosen by scientists does not cause acidification of the defect site, which can slow down or even stop the regeneration process.

The barrier membrane also works as a framework that keeps the grafts in the right position and creates conditions for the growth of bone cells in damaged areas. And its antibacterial coating protects the defect area from infection.

-Almost every jaw bone repair and augmentation surgery includes a membrane placement stage. Up to 90% of patients planning to place implants on the upper jaw and up to 50% on the lower jaw need bone augmentation due to bone atrophy. The development of biodegradable polymer membranes for targeted bone regeneration responds to the growing need for effective methods of treatment of bone tissue defects, " said Anna Cheremnykh, lead engineer of the research project of the Scientific and Educational Laboratory of Tissue Engineering and Regenerative Medicine at NITU MISIS.

How the invention will simplify the work of dentists

Such membranes are widely used in maxillofacial surgery and implantology to treat bone defects of the jaws. When surgery is performed, the mucosal periosteal flap is first peeled off to gain access to the diseased area. After a pathologic mass (such as a cyst or tooth) is removed, a cavity is created in the bone. If it is not protected, scar tissue will sprout inside and prevent new bone from forming. Membranes can also be used for the preservation of wells for implantation, explained "Izvestia" professor of the Department of Surgical Dentistry VSMU named after N.N. Burdenko Ilya Stepanov.

- Osteopathic material is introduced into the bone cavity. It can be synthetic bone, bone of animal origin or human. And in order to form a new bone, it is necessary to isolate the bone wound with a membrane, where we have previously introduced this material. For example, in the case of bone atrophy, titanium mesh is used. It works as a framework. Bone material is placed under it. But then it will have to be removed. There are membranes based on halogen or other materials, but they resorb too quickly or create an acidic environment, so healing is worse," said the expert.

The membrane proposed by the experts degrades in a few months. This time is enough for the material placed under it to form normal bone tissue. Then it resorbs without changing the acid-alkaline balance in the wound area, the expert added.

- Thanks to this achievement of Russian scientists, dentists will not have to buy all this stuff abroad, as we had to do in recent years. This is one of the reasons why prices are rising in dentistry. And the delivery of these materials has become a serious problem. Such a membrane is a big plus for the patient, because he does not have to make a second incision, to clear everything there. And the doctor will be able to proceed much faster to the next stage of treatment, which will accelerate healing, - said dentist, orthodontist, member of the Professional Society of Orthodontists of Russia Maria Balakireva.

For the safe use of the membrane requires detailed research, how after the decomposition of the material its components will be removed from the body, emphasized dentist Alexei Antipenko.

- If these polymers decompose, they will enter the bloodstream, so to assess their safety, it is necessary to understand what parts of the body they will eventually enter and where they can stay for a long time. The potential for the materials used to cause, for example, cancer must also be assessed. We need preclinical and clinical studies, which can take up to 10 years," he said.

It is important to check the polymer itself, from which the membrane is made, for allergic reactions from the human body and cytotoxic properties in relation to the tissues of the area of surgery. These parameters are extremely important, said Alyona Kulikova, a dental surgeon and assistant of the Department of Therapeutic Dentistry at PFUR.

Переведено сервисом «Яндекс Переводчик»