Hull approach: Russian 3D fabric will make UAVS more impact-resistant

Russia has developed a technology for the mass production of sheet polymer composite material based on 3D fabric. This material provides increased impact resistance for drones and eliminates the risk of coating stratification under high loads and machining, eliminating a common problem with standard composites. Experts note that this fabric can be used not only to equip drones, but also other important aircraft facilities. For more information about the technology, see the Izvestia article.

What is 3D fabric and how does it work?

In Russia, with the support of the NTI Foundation (National Technology Initiative), they plan to launch the country's first mass production of a sheet polymer composite material based on 3D fabric. This material is intended for the hulls of drones and other aviation equipment. It is produced using a special pultrusion technology, a continuous technological process that makes it possible to produce composite products quickly and in large volumes.

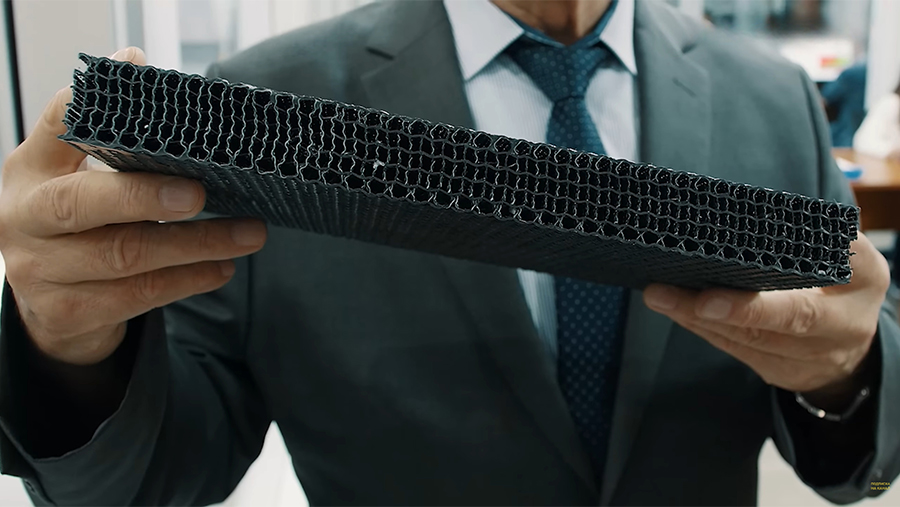

The main difference between the new product is the use of three—dimensional carbon fiber fabric. This structure is much stronger than the usual layered materials: it makes the material more resistant to impact and prevents its stratification during loading and processing, which was previously a serious problem. The development uses a Russian—made three-dimensional preform, a single-layer reinforced fabric. Previously, such composites were manufactured using the technology of layer-by-layer laying, also known as "contact molding".

As noted in the press service of the Carbontex development company, their goal is not only to create a material with improved strength characteristics, but also to organize its high-speed and cost-effective production.

"The abandonment of labor—intensive manual layering will significantly reduce the cost and bring affordable high—quality carbon fiber of domestic production to the market," the press service added.

The developers note that the transition to an automated process will significantly reduce the cost and speed up production. In the future, domestic industrial-grade carbon fiber plastics with affordable price and high quality will appear on the market. The material will be produced in sheets up to 1 m wide and 2 to 6 mm thick. It demonstrates stable milling performance, is not subject to delamination and is resistant to significant impact loads.

The company noted that major Russian companies are already among the customers: Almaz-Antey, Rosatom, Rostec. The first prototype is planned to be released in 2025, and mass production in 2026. By 2027, the company expects to occupy up to 10% of the Russian carbon fiber market.

Where the new technology will be useful

In the production of carbon fiber, its strength, elasticity and resistance to fracture are determined by the type of carbon fiber weaving, Sergey Kurapov, a researcher at the Razumovsky Moscow State Technical University, told Izvestia.

— The three-dimensional type of weaving provides the most durable fabric capable of withstanding extreme loads. Such a material can be used in the production of UAVs that solve important tasks, with expensive high-precision equipment installed in the aviation industry and other areas where durable and lightweight composite materials are required. The availability of such production in our country will allow us to increase the volume of production of military and civilian UAVs, regardless of foreign policy factors and sanctions," he explained.

This material is planned to be used not only for the exterior cladding of drones, but also to protect other important parts of aviation equipment. Svyatoslav Pegov, director of the Center for Sports Programming, Algorithmic Robotics, Cybersecurity and Esports at Ufa University of Science and Technology, believes that since the material is lightweight, durable and more reliable than many analogues, its implementation "can be a step forward in creating stronger and more resilient drones and airplanes" that will be better protected and last longer.

— This development will find application in areas where the combination of low weight, high strength and load resistance is critically important. These are unmanned aircraft, manned aircraft manufacturing and other high-tech industries. Modern UAV protection technologies involve structural survivability, the use of active and passive protective equipment," said Igor Bederov, a representative of T.Hunter.

Any development should be based on the requirements of drone operators, says Dmitry Kuzyakin, chief designer of the Center for Integrated Unmanned Solutions.

— I have not heard that the front or other customers are in need of new fabrics for drones. On the other hand, it is not known in advance what will turn out to be a really necessary and breakthrough solution, and what will disappear into history. As "drowned" solutions, I can recall drone delivery or drone taxi. How much money was spent on this, not only in Russia, but all over the world," he said in an interview with Izvestia.

According to the expert, the issues of organizing communications resistant to electronic warfare (electronic warfare), increasing the range of drones and expanding the range of application scenarios remain much more urgent to protect UAVs.

Переведено сервисом «Яндекс Переводчик»