Reducing heat: import substitution of materials for electronic boards in the Russian Federation

- Статьи

- Science and technology

- Reducing heat: import substitution of materials for electronic boards in the Russian Federation

Russian scientists have developed a new method of producing thermoplastics. Thanks to this method, polymers with increased heat resistance are created. The development will help with import substitution of foreign materials, primarily in the field of electrical engineering and instrumentation. Now thermoplastics are produced only abroad, so experts agreed that their development and the development of methods of their synthesis will significantly help the growth of domestic industry.

Spheres of application of "Bauman thermoplastics"

A new way of creating polymers with increased heat resistance has been found by scientists of the Center of STI "Digital Materials Science" of Bauman Moscow State Technical University. It allows import substitution of those materials that were previously produced only abroad. Experts note: the greatest benefit of the new polymers will come to the instrument-making and electrical engineering industries, as they will make it possible to make the production of flexible printed circuit boards and electrical connectors for aircraft more efficient and cheaper. Their use will also improve the medical industry: thermoplastics are needed in the creation of machine parts for the production of infant formula, filtration panels, heat exchangers, endoscopic probe tips and other devices.

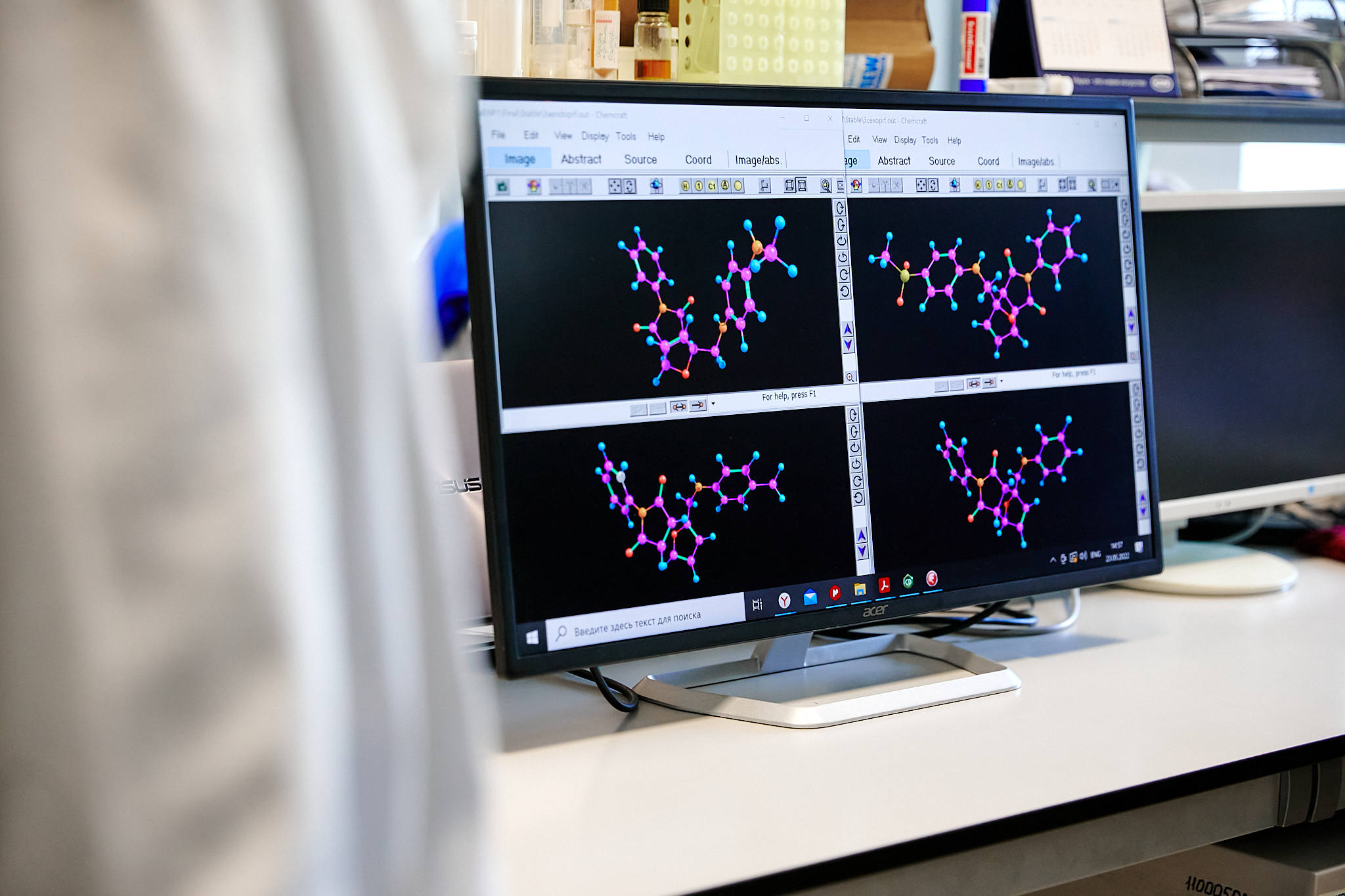

- In recent years there is an active development of new methods of synthesis and processing of superconstructive polymeric materials. Interest in them is due to their high performance characteristics. We are actively working on scaling up the synthesis of polyarylates, polyethersulfones and polyetherimides. These polymers are of great interest for creating a new generation of high-temperature resistant materials. These thermoplastics are resistant to radioactive radiation, flame retardant, have high chemical resistance, and are resistant to fuels and oils. A striking example of such resources can be sopolyimides and polyetherimides developed by us, which are not worse, and in some parameters even a little better than their foreign counterparts: Ultem 1000 and Exterm brands from the well-known world manufacturer SABIC, - said the leading engineer of the STI Center "Digital Materials Science: New Materials and Substances" of Bauman Moscow State Technical University Vadim Istomin.

According to the expert, the use of own materials and the development of domestic base of synthesis of complex polymers can significantly reduce the cost of organizing new production facilities. The area of increasing the efficiency of thermoplastics is almost limitless and depends on the requirements to the performance characteristics of the final product. This factor is the main direction in the field of research of new materials properties, Vadim Istomin specified.

- Superconstructive polymer materials can be used in many industries: aircraft rocket building, mechanical engineering, electrical engineering and 3D printing. The application of new materials in the field of medicine and medical instrumentation looks especially promising. For example, housings of medical devices, units and equipment, as the main requirement is high strength and biological inertness of the material. Elements of prostheses and implants are also a promising area of their use. Also "Bauman thermoplastics" will find their application in the technology of prepregs production, which can be used in aircraft and machine-building fields, construction sector, composite industry, - the expert explained.

How experts assess the novelty

Active application of such polymers is limited by one factor - the cost of their production. Complex cyclic processes greatly increase the cost of their production, says the commercial director of the company "Laboratory of the Future" Pavel Kamnev. The expert is convinced that these polymers due to their properties, such as resistance to temperature, insulating properties, strength, low smoke and gas emission, have a wide enough potential for application in the electric power industry, air transport, ships, space industry. In addition, parts made of PEI are actively used in machines and mechanisms.

- The development of the industry should be expected precisely in the simplification of obtaining these materials, refinement of technologies and development of technological equipment. But it is only a matter of time, - predicted Pavel Kamnev.

Thermoplastics have unique characteristics, such as increased heat resistance, chemical resistance, durability and ease of processing, respectively cheaper and more durable solutions. In addition, thermoplastics can often be recycled, which is good for the environment, says Ruslana Permyakova, deputy director of the NTI Competence Center "Trusted Interaction Technologies" on the basis of TUSUR.

- A wide range of impact- and heat-resistant plastic is an urgent need for any modern production of high-tech products, from UAVs to medical equipment. Our scientists apply proven methods of molecular modeling based on artificial intelligence technologies. However, the practical "output" from such developments will be determined not in university laboratories, but at production sites, - said Alexander Rodin, a leading expert of the Center of STI Competences "Artificial Intelligence" on the basis of MIPT.

Thermoplastic justifies the investments made in the development only in mass production, and whether the owner of the technology will be able to meet the demand for the necessary number of products to make it profitable is the key issue of survival of such solutions in the market. Therefore, the future of the industry of new materials is entirely in the hands of industrial partners who are interested in obtaining a real product, he said.

The importance of import substitution has been repeatedly expressed by top government officials. In particular, the head of the Central Bank Elvira Nabiullina back in April 2022 spoke about sanctions, because of which Russian sewing production faced difficulties in purchasing sewing accessories.

- It is very important for all of us to expand supply bottlenecks related both to labor shortages and infrastructure bottlenecks, and to stimulate productivity, investment in productivity growth, - said Elvira Nabiullina at a press conference following the meeting of the Central Bank's Board of Directors on monetary policy.

Now in the instrumentation industry thermoplastics are used to create flexible printed circuit boards, self-adhesive tapes and insulation of electrical circuits. And in medicine they are used to create products that must be sterilized and have high biocompatibility, Ruslan Permyakov stressed.

Переведено сервисом «Яндекс Переводчик»